Pioneers in Europe betting on LNG-CNG gas stations with buried tank

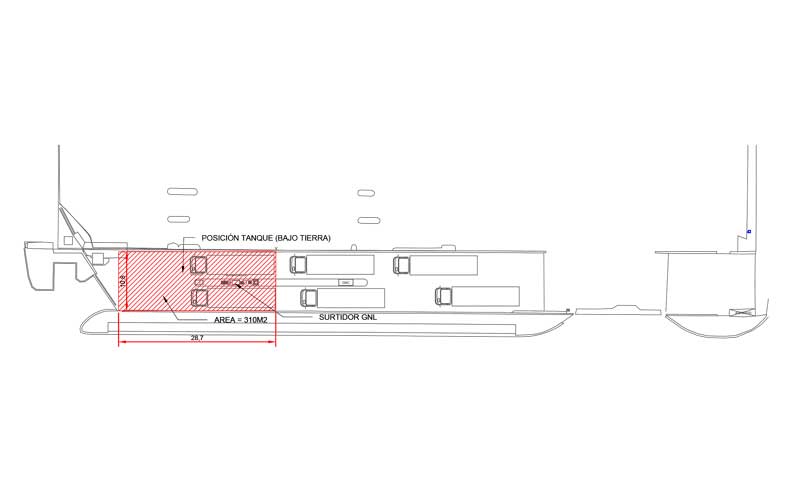

Yellow Project is the HAM Group commitment to the construction of CNG-LNG service stations in confined spaces. The construction of a gas station implies the installation of large equipment, such as the tank, which requires large surfaces to be placed, respecting all the established security measures, which ends up reducing the useful space for the installation of liquefied natural gas (heavy vehicles) and compressed natural gas dispensers (passenger car and trucks).

HAM Criogénica, together with our R&D team, has been in charge of the development of the Yellow Project, which proposes the burial of the gas tank under the circulating area of the service station, thus allowing the installation of a large storage volume without impacting the gas station circulation flows, thus providing a larger and safer surface. All equipment has been designed and manufactured in our facilities and those of Vakuum, a HAM Group company specialized in the design, production of semi-trailers and mobile units for the transport of LNG and Air gases, following the latest innovations and quality regulations and EU and ASME design.

The first CNG-LNG service station that is part of the Yellow Project is the new gas station that we have designed, built and commissioned in Irún, Gipuzkoa. It is an ultra-compact gas station, on a surface of only 310m2, located in Antxotxipi Kalea 4 (How to get there), next to the AP-8, also known as the Cantabrian Highway.

The buried tank of the service station has 80,000 liters of LNG capacity, works at low pressures (3 bar), has a submerged pump and can supply up to 12,000kg/h of LNG and 10,000 kilos of CNG per day. The gas station has an buried coldbox, an "on the fly" conditioning system and allows the installation of up to 2 dispensers (4 nozzles) of Liquefied Natural Gas and 1 double dispenser (2 nozzles) of Compressed Natural Gas.

The CNG-LNG service station, safer and with less necessary safety distances, is monitored remotely, guaranteeing its perfect operation and allowing any incident to be solved quickly.

The design is also compatible with international ISO standards and, especially, with french standards 4718, 1413 and 1414.

At HAM Group we work daily, in continuous contact with our customers, suppliers and manufacturers, to develop high-quality and reliable advances in the improvement of CNG-LNG infrastructure and logistics services, taking respect for the environment as a starting point.